Introduction Type of Seam

Seam classification plays a pivotal role in the garments industry, offering a systematic approach to categorizing and understanding various stitching techniques employed in garment making. Each seam class serves a specific purpose, contributing to the final product’s functionality, durability, and aesthetics. A seam is a joint where two or more ply or layers of fabric are stitched and held together. Industrial sewing machines are commonly used to sewing seams in mass-produced clothing, footwear, household textiles, and sporting goods.

The objective of Different Types of Seams Classification

- Know about different types of seams

- Identify seams by looking at stitches

- Know about the formation & construction process of various seams

Types of Seams With Pictures

Seams are classified into eight classes based on the type and number of components used, as defined in ISO 4916:1991.

A seam type is a formal description of a seam’s configuration. There are six main classes of seam types, with two additional classes used presently.

- Seam Class-1: Super Imposed Seam

- Seam Class-2: Lapped Seam

- Seam Class-3: Bound Seam

- Seam Class-4: Flat Seam.

- Seam Class-5: Decorative Seam

- Seam Class-6: Edge Neatening

- Seam Class-7: Applied Seam

- Seam Class-8: Enclosed Seam

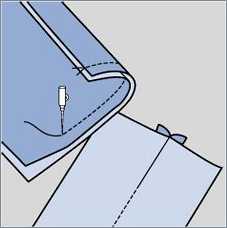

Class 1 Superimposed seam

The class-1 seam is the superimposed seam, the most commonly used technique for joining fabrics. Two layers of fabric are placed on top of one another and then sewing together.

Used of Superimposed Seam

The side seam of the T-shirt, the Trousers’ side seam, and the Cuff’s side seam.

Sketch

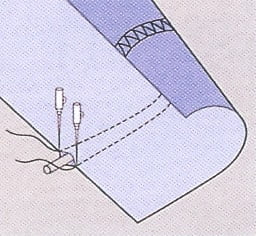

Class 2 Lapped seam

The lapped seam, a type of class 2 seam, requires at least two plies of fabric to produce this type of seam

Used of Lapped Seam

The side seam of the shirt, pants, pocket attachment, etc.

Sketch

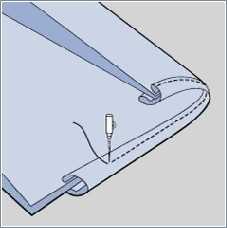

Class 3 Bound seam

To create a bound seam, at least two layers of fabric are required. This type of seam is also known as a class-3 seam. In a bound seam, the edge of one layer of cloth is enclosed by the other layer. A folder is used in the sewing machine to produce a neat and secure bound seam.

Used of Bound Seam

Neck binding, Body binding, underwater fly piping, and armhole binding.

Sketch

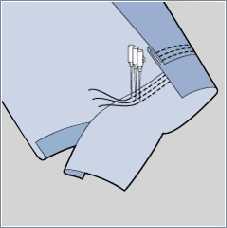

Class 4 Flat seam

The seam of class 4 is called a flat seam, where two pieces of fabric are sewing together using zigzag stitches by a two-needle sewing machine.

Used of Flat Seam

Raglan of the sweatshirt, Zigzag stitch, and Scallop.

Sketch

Class 5 Decorative seam

The decorative seam is classified as a class-5 seam and is used for decorative purposes. To create this type of seam, the fabric is folded several times and then stitched according to the underside of the folded part of the fabric.

Used Decorative Seam

Curtains, Table cloths, Furniture, Decorative ladies’ wear etc.

Sketch

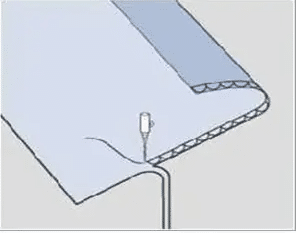

Class 6 Edge Neatening

The seam of class-6- is called edge neatening, which is used to hold the edge of the fabric. All the lock stitches are edge-sealing class seams.

Used of Edge Neatening

Single fold hem, Double fold hem, and T-shirt hem.

Sketch

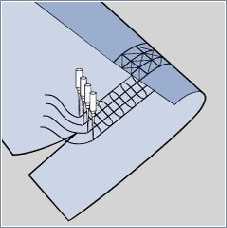

Class-7 Applied Seam

This type of seam is similar to the lapped seam (Seam Class-2), but with the difference that the joined component is extended on both sides of the sewn line. This type of seam is used to join different parts of garments with additional or extra materials such as lace, elastic braid, or elastic. A multi-need sewing machine and folder are used to produce this seam. If this function is involved, it will be easier to create.

Class-8 Enclosed Seam

The fabric’s edges are folded and sewing in various ways using a folder. This process allows the seam to be made in one go and completed using a twin-needle machine and folder.

Advantages of Different Types of Seams Classes

- Enhanced Versatility: Knowledge of various seam classifications enables designers to experiment with different stitching techniques, expanding their creative repertoire.

- Improved Quality Control: Understanding seam classes facilitates better quality assessment and ensures compliance with industry standards.

- Tailored Solutions: Different garments require specific seam types based on their fabric, design, and intended use, and knowing the appropriate seam class helps in achieving optimal results.

Conclusion

This experiment teaches us about different types of seams, and this seam classification helps identify the stitch type and sewing thread used in each application. Seam classification is a fundamental aspect of garment construction, influencing the quality, functionality, and aesthetics of apparel. The characteristics and applications of different seam classes, designers and manufacturers can optimize their processes and deliver high-quality garments that meet consumer expectations.

Also Read: Different Types Of Stitches In Garment Industry With Picture

FAQs (Frequently Asked Questions)

What are the 5 types of seams?

The five types of seams commonly used in garment construction are:

1. Superimposed Seam

2. Lapped Seam

3. Bound Seam

4. Flat Seam

5. Decorative Seam

What are the three types of seam finishes?

The three types of seam finishes commonly used in garment construction are:

1. Zigzag Stitch

2. Overlock Stitch (Serger)

3. Bound Seam

How many types of seams are there?

1. Seam Class-1: Super Imposed Seam

2. Seam Class-2: Lapped Seam

3. Seam Class-3: Bound Seam

4. Seam Class-4: Flat Seam.

5. Seam Class-5: Decorative Seam

6. Seam Class-6: Edge Neatening

7. Seam Class-7: Applied Seam

8. Seam Class-8: Enclosed Seam