What is Method Study?

Method study, also known as methods engineering or work study, is a systematic and scientific technique to improve work methods and processes. It involves analyzing and evaluating existing methods to identify inefficiencies and develop more effective alternatives. In the garment industry, where complex processes are involved in manufacturing various apparel items, the method of study helps streamline operations and enhance overall efficiency.

Objective of Method Study

The primary objectives of method study in the garment industry include:

- Increase Efficiency: Eliminate unnecessary motions, reduce waste of time and resources, and streamline processes to maximize productivity.

- Reduce Costs: Identifying and removing inefficiencies also helps reduce production costs, including labor, materials, and overhead expenses.

- Improve Quality: By standardizing methods and reducing variability, method-study improves product and service quality.

- Enhance Safety: It helps identify and eliminate hazards and risks associated with work methods.

- Optimize Resource Utilization: By analyzing resource usage and optimizing processes, method-study ensures efficient utilization of materials, equipment, and manpower.

6 Sequence of Method Study

- Define the problem

- Obtain all the facts relevant to the problem

- Examine the facts critically but impartially

- Consider the courses open and decide which to follow

- Act on the decision

- Follow up on the development

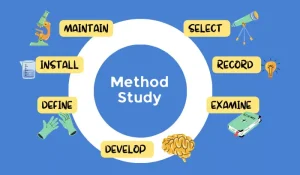

7 Steps of Method Study

Method study typically follows a structured approach, including the following steps:

- Selecting the Work or Operation to be Studied: Involves choosing a specific task or operation within the garment manufacturing process for analysis.

- Recording the Current Method: Detailed observations are made to record each step of the current method or process used to perform the selected task.

- Examining the Method: The recorded information is thoroughly examined to identify any inefficiencies, unnecessary steps, or opportunities for improvement in the current method.

- Developing and Evaluating Alternative Methods: The most practical, economical, and effective method, Having due regard to all contingent circumstances.

- Implementing the Preferred Method: Once the best alternative is selected, it is implemented in garment manufacturing. The new process is so that it can always be identified.

- Install: That method is standard practice

- Follow-Up and Monitoring: Common practice through routine checks

Application of Method Study in the Garments Industry

Method study finds extensive application in various aspects of garment manufacturing, including:

- Cutting and pattern-making processes

- Sewing and assembly operations

- Finishing and quality control procedures

- Material handling and logistics

Benefits of Method Study in Garments Manufacturing

Implementing method study techniques in the garment industry yields several benefits, such as:

- Increased productivity and output

- Reduced production costs and waste

- Improved quality and consistency of finished products

- Enhanced worker safety and morale

- Better utilization of resources and equipment

Tools and Technique of Method Study

- Motion economy

- Ergonomics

- Workplace engineering

- 5S

Conclusion

In conclusion, the method of study plays a vital role in enhancing efficiency, productivity, and quality within the garment industry. By systematically analyzing and optimizing work processes, manufacturers can significantly improve their operations, resulting in cost savings, improved product quality, and better utilization of resources. Method-study is a part of Industrial engineering and essential for staying competitive in this dynamic and competitive industry.

Also Read: 5 Basic Work Measurement Techniques For Garments Industry

Check out our YouTube video about Method of Study In the Garments Industry.

FAQs (Frequently Asked Questions)

What is method study, and why is it important in the garment industry?

Method of study is a systematic technique for analyzing and improving work methods and processes. In the garment industry, where efficiency and productivity are crucial, method study helps optimize operations, reduce costs, and enhance product quality.

What are some common challenges in implementing method study in garment manufacturing?

Challenges in implementing method of study in garment manufacturing may include resistance to change, limited resources, complexity of processes, and balancing efficiency with flexibility.

How does method study contribute to sustainability in the garment industry?

By optimizing processes and reducing waste, method of study can contribute to sustainability efforts within the garment industry, promoting eco-friendly manufacturing practices and resource utilization.