The AQL chart is a critical tool in the garment industry for maintaining quality control standards. It helps manufacturers decide the number of samples to inspect from a batch.

The garment industry is always pressured to deliver products that meet or exceed customer expectations. Quality control plays a pivotal role in ensuring that each piece of clothing meets the set standards before it reaches the consumer. The AQL (Acceptable Quality Level) chart is an indispensable component of this quality control process.

What is AQL (Acceptable Quality Level)?

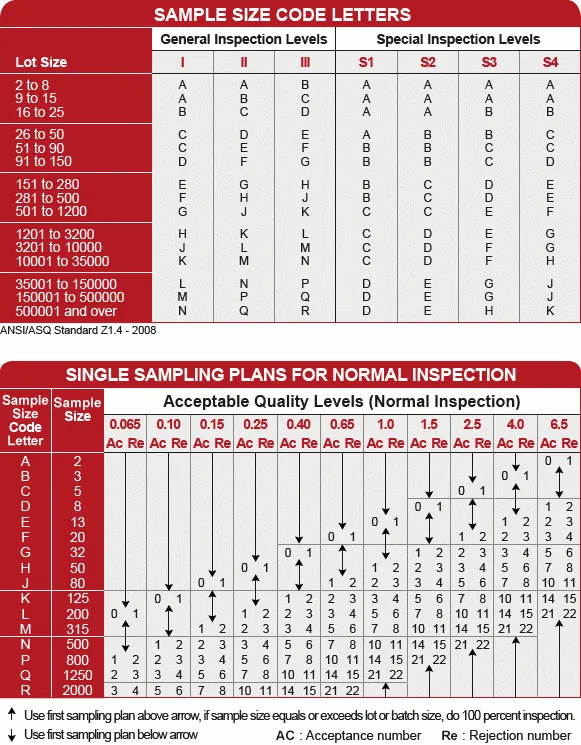

AQL, or Acceptable Quality Level, is a critical tool in the garment industry for maintaining quality control standards. It helps manufacturers determine the number of samples to inspect from a batch and decide whether to accept or reject it based on predetermined criteria.

The Importance of AQL in Garment Quality Control

In the highly competitive garment industry, maintaining consistent quality is paramount. AQL plays a pivotal role in:

- Ensuring products meet or exceed customer expectations

- Balancing quality requirements with production efficiency

- Facilitating clear communication between manufacturers and buyers

What Are AQL Numbers

AQL numbers represent different quality standards:

- AQL 1.0: High-quality standard for minimal defects

- AQL 2.5: Common standard for general products

- AQL 4.0: More lenient, suitable for non-critical items

Lower AQL values indicate higher quality expectations. Manufacturers choose these numbers based on product requirements and market needs.

The AQL Table: A Key Quality Control Tool

The AQL table is essential for determining:

- The sample size for inspection

- Maximum acceptable number of defects

Based on the chosen AQL level, the table provides guidelines for how many items to inspect and the allowable defects for the lot to pass inspection.

The AQL (Acceptable Quality Limit) standard used for product inspection depends on the price and quality of the product. Higher-priced garments generally require a stricter AQL standard, such as AQL 1.0, while lower-quality and lower-priced clothes may have a lower AQL standard, such as AQL 6.5. The AQL system is commonly used in the garments industry for final inspections.

5 Key Applications of AQL in Garment Inspection

- Pre-Production Inspection: Checking raw materials and machinery before production begins

- In-Line Inspection: Monitoring quality during the production process

- Final Inspection: Assessing completed garments before packing and shipping

- Random Sampling Inspection: Using AQL standards to inspect a representative sample

- 100% Inspection: Thoroughly checking every single garment for critical products

Benefits of Implementing AQL Inspection

Improved Product Quality

- Ensures consistent quality across batches

- Identifies defects early in the production process

- Maintains high customer satisfaction levels

Cost Reduction

- Minimizes expenses related to defects and rework

- Reduces waste and scrap materials

- Increases overall production efficiency

Conclusion

Implementing AQL charts in your quality control process can significantly enhance the accuracy and efficiency of garment inspections. By setting clear acceptance criteria, you can:

- Streamline your inspection process

- Reduce production costs

- Boost customer satisfaction

Remember, the right AQL standard depends on your product type, price point, and target market. Regularly review and adjust your AQL standards to ensure they align with your quality goals and customer expectations.

Also Read: The Role Of Quality Control In Garments Industry (QC)

FAQs Frequently Asked Questions

What Is An Aql Chart?

An Aql Chart, also known as Acceptance Quality Limit chart, is a statistical tool used in quality control to determine the acceptable and non-acceptable levels of defects in a production sample. It helps ensure that the products meet the required quality standards.

How To Use An Aql Chart?

To use an Aql Chart, determine the acceptable quality level (AQL) based on the criticality of the product, select a sampling size, conduct inspections, and compare the number of defects found to the AQL limits. It helps in making informed decisions about product acceptance or rejection.

Why Is Aql Chart Important In Manufacturing?

The Aql Chart is important in manufacturing as it helps in setting quality standards, ensuring consistency in product quality, and reducing the risk of accepting defective products. It allows manufacturers to maintain quality control and meet customer expectations, thus enhancing their reputation and trust in the market