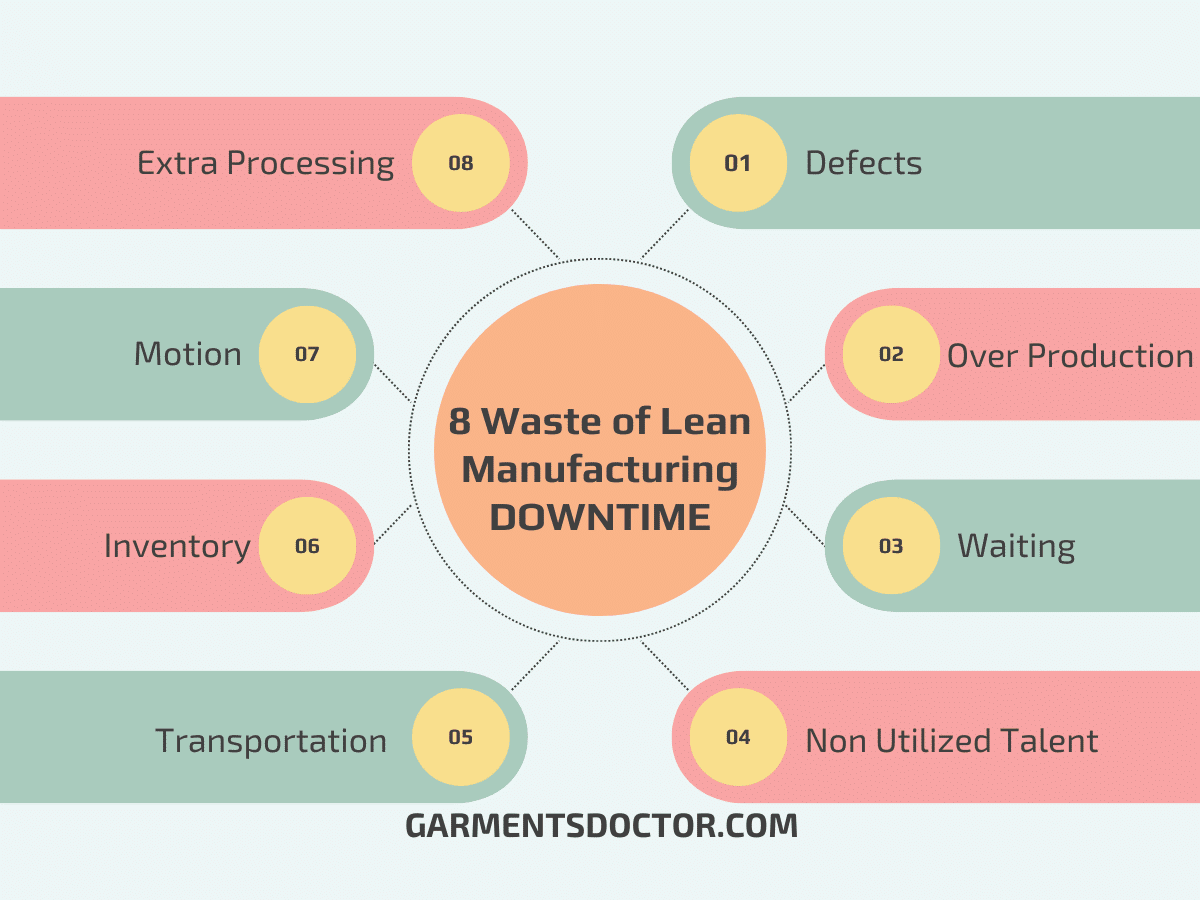

The 8 waste of Lean Manufacturing in the garments industry are defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, and excessive processing. These wastes significantly impact efficiency and productivity.

In the competitive world of the garments industry, optimizing operations is crucial for success. Lean Manufacturing principles offer a roadmap to eliminate waste and enhance value for customers. Recognizing and addressing the 8 wastes can lead to remarkable improvements in production speed, cost reduction, and overall quality.

This approach not only streamlines processes but also boosts employee morale by involving them in problem-solving and decision-making. By focusing on these areas, businesses can achieve a leaner, more efficient operation that stands out in the marketplace. Embracing Lean Manufacturing practices is a strategic move towards sustainable growth in the fast-paced garments industry.

Introduction To Lean Manufacturing In The Garment Industry

Lean Manufacturing revolutionizes how we see production. In the garment industry, it means more with less. Less waste, less time, and less space. It’s all about streamlining operations. Factories become nimble and efficient. This approach can transform the garment sector.

The Lean Philosophy

At the heart of Lean Manufacturing lies the drive to maximize value. We cut out anything not adding to the product. That means no unnecessary steps. Every action must make sense. It’s a philosophy that empowers workers and simplifies processes.

- Focus on value

- Eliminate waste

- Continuous improvement

Impact On The Garment Sector

Lean principles have a big effect on garment manufacturing. Production times drop. Costs go down. Quality goes up. Workers are happier. Customers get their products faster. It’s a win-win across the board.

Before Lean | After Lean |

|---|---|

Long production cycles | Shorter lead times |

High inventory levels | Just-In-Time inventory |

Quality issues | Improved quality control |

Defining 8 Waste of Lean Manufacturing as a DOWNTIME

In the world of Lean Manufacturing, waste means trouble. Identifying the 8 Wastes of Lean is like being a detective. We look for clues that show us what needs fixing in a factory. Especially in the garments industry, finding and fixing these wastes can make a big difference.

Overview Of The 8 Wastes

- Defects: Mistakes in products that need fixing.

- Overproduction: Making more than needed.

- Waiting: Time when work is not happening.

- Non-utilized Talent: Not using workers’ skills well.

- Transportation: Moving things more than needed.

- Inventory: Having more materials than needed.

- Motion: Extra steps or movements by workers.

- Extra-processing: Doing more work on a product than needed.

Waste

What It Means

Example in Garments Industry

Defects

Making mistakes in products.

Wrong stitching on a shirt.

Overproduction

Making more products than sold.

Too many shirts, not enough buyers.

Waiting

Time when nothing is being made.

Machines not used all day.

Non-utilized Talent

Not using workers’ skills.

Designers doing basic tasks.

Transportation

Moving things too much.

Fabric moved around many times.

Inventory

Too much material on hand.

Boxes of unused fabric.

Motion

Extra steps by workers.

Walking far for tools.

Extra-processing

More work on a product than needed.

Adding extra stitches not wanted.

1. Waste Of Defects

Waste of Defects stands as a significant challenge in the garments industry. It refers to products that do not meet quality standards. These garments often require rework or become waste. It leads to resource loss, increased cost, and customer dissatisfaction. Understanding and reducing defects is crucial for lean manufacturing success.

Quality Control And Continuous Improvement

Quality control is essential for detecting and preventing defects. It ensures products meet set standards. Regular checks keep quality high. Continuous improvement means always finding ways to get better. It involves everyone in the company. This approach helps in keeping defects to a minimum.

- Implementing inspections at various production stages

- Training workers to understand quality requirements

- Feedback loops that inform about defects quickly

Reducing Defect Rates

Reducing defect rates is vital for lean manufacturing. It saves time and materials. It also keeps customers happy. There are proven methods to reduce these rates effectively.

- Standardizing work processes to maintain consistency

- Using the right tools and equipment to ensure precision

- Root cause analysis to understand why defects occur

2. Waste Of Overproduction

Lean manufacturing aims to cut waste. In the garments industry, overproduction is a big waste. It means making more clothes than needed. This can cost a lot and cause problems.

Consequences In Garment Manufacturing

Overproduction in the garments sector can lead to:

- Extra stock, taking up space.

- More money tied up in goods.

- Products may become outdated quickly.

- Higher risk of discounts to clear stock.

- Resources get used up unnecessarily.

Strategies To Reduce Overproduction

To avoid making too much, try these steps:

- Just-In-Time (JIT) production.

- Understand customer demand better.

- Use data to plan production.

- Improve communication in the supply chain.

- Automation to adjust quickly.

- Train staff on lean principles.

3. Waste Of Waiting

The Waste of Waiting stands out in garment manufacturing. It happens when workers wait for materials, machines, or approvals. This waste slows down production. It can cost companies time and money. Recognizing the impact of waiting is critical. Let’s explore its effects and solutions.

Effects On Workflow And Efficiency

Waiting creates a domino effect. It disrupts the workflow. It lowers efficiency. Workers cannot complete tasks on time. Idle machines and staff become common. This leads to missed deadlines. It also increases the cycle time. Overall, waiting can cause a significant drop in production.

- Idle workers: Time is wasted when employees are not active.

- Machine downtime: Idle machines do not generate revenue.

- Missed deadlines: Delays can lead to unhappy customers.

Solutions To Minimize Downtime

Reducing waiting time boosts productivity. Here are strategies to minimize downtime:

- Streamline supplies: Ensure materials arrive on time.

- Preventive maintenance: Regularly check machines to avoid breakdowns.

- Clear communication: Quick information flow prevents delays.

Implementing a Just-in-Time (JIT) system is also effective. It reduces inventory costs. It ensures materials are available when needed. Cross-training workers is beneficial too. It allows staff to handle multiple tasks. This keeps them productive during machine downtime.

Strategy | Benefit |

|---|---|

Just-in-Time System | Reduces inventory, ensures material availability |

Cross-Training | Keeps workers productive, adds flexibility |

4. Waste Of Underutilized Talent

The Waste of Underutilized Talent is a major issue in the garments industry. Many companies overlook the skills and ideas their employees have. This waste means losing out on innovation and growth. Let’s explore how to tap into this untapped resource.

Harnessing Employee Potential

Employees in the garments industry often have hidden talents. Companies must recognize and use these skills. Here are ways to do that:

- Identify individual strengths – Know what each person does best.

- Training programs – Offer chances to learn and grow.

- Empowerment – Let employees make some decisions.

- Open communication – Talk and listen to staff ideas.

Encouraging Innovation And Engagement

Innovation drives the garments industry forward. Engaged employees bring new ideas. Here’s how to encourage them:

- Reward creativity – Give bonuses for great ideas.

- Collaborative culture – Work together to solve problems.

- Innovation workshops – Host events to brainstorm.

- Feedback loops – Share results from new ideas.

5. Waste Of Transporting

In the garments industry, Waste of Transporting is a big issue. This waste happens every time materials move more than needed. Too much moving can cost a lot of money and time. Let’s see how we can fix this problem.

Optimizing Material Movement

To reduce waste, it’s key to move materials smartly. First, we need to understand the path materials take. Then, we can make this path shorter or simpler. Here are some steps to do this:

- Map out the current movement of materials.

- Identify any unnecessary steps.

- Redesign the layout to shorten the distance materials travel.

- Use signs and labels to guide material movement.

Streamlining Internal Logistics

Improving how things move inside the factory is also key. This is called streamlining internal logistics. Here are some ideas:

- Group machines and tools by the type of work they do.

- Make sure all needed materials are close to where they are used.

- Train workers on the best ways to move materials.

- Use carts or conveyor belts to make moving things easier.

By focusing on these areas, the garment industry can cut down on waste. This leads to saving both time and money.

6. Waste Of Excess Inventory

The Waste of Excess Inventory is a big challenge in the garments industry. Too much inventory ties up money. It can lead to waste from products that become outdated. Let’s learn how to control inventory better.

Managing Inventory Levels

Keeping the right amount of inventory is key. Here are ways to do it:

- Regular audits: Check what you have often.

- Use software: It helps track items well.

- Analyze data: Understand what sells fast.

- Train staff: They should know about managing stock.

Just-in-time Inventory Systems

Just-In-Time (JIT) systems keep inventory low. They make sure new stock comes right when needed. Here’s how JIT helps:

Benefits of JIT |

|---|

Less money stuck in stock |

Fewer outdated products |

More room in warehouses |

Better response to trends |

JIT needs good relationships with suppliers. It also needs a flexible production schedule. This way, the factory can make products fast.

7. Waste Of Motion

The Waste of Motion is a key area in lean manufacturing. It involves any movement that does not add value. In the garments industry, this waste can slow down production. It can also tire workers out. Let’s dive into how to reduce this waste.

Ergonomics And Workflow Design

Good ergonomics is crucial in reducing waste of motion. It keeps workers safe and comfortable. A well-designed workflow prevents unnecessary steps. This leads to a smoother process.

- Adjust workstations to the right height.

- Arrange tools within arm’s reach.

- Use equipment that reduces strain.

Reducing Unnecessary Movements

To cut down on unnecessary movements, plan each task carefully. Make sure each step has a purpose. Remove steps that do not add value.

- Observe the current workflow.

- Identify any wasteful steps.

- Redesign the process to eliminate them.

By focusing on these areas, the garment industry can work smarter. It can also save time and energy. This leads to better productivity.

8. Waste Of Over-processing

Over-processing stands as a key waste in lean manufacturing. It happens when garments go through more steps than needed. Extra processes cost time and money, and they can lower quality. In the garments industry, cutting out over-processing boosts efficiency and product value.

Identifying Unnecessary Processes

Spotting extra steps is step one. A detailed review of the production line is vital. Teams can map out every task involved. They look for actions that don’t add value. Common signs include:

- Repeat inspections

- Excess handling of materials

- Unneeded adjustments on machines

Simplifying Production Steps

After finding the extra steps, it’s time to streamline. The goal is to make the process leaner. This involves:

- Combining similar tasks

- Removing redundant quality checks

- Training workers for multi-skilled roles

Simplification means doing only what’s essential. It ensures quality and cuts costs. The garments industry benefits from fewer steps and higher efficiency.

Benefits of Implementing Lean In Garment Manufacturing

Reducing waste in lean manufacturing offers numerous benefits, including:

- Cost savings through reduced inventory, lower scrap rates, and improved resource utilization.

- Improved lead times and on-time delivery, enhancing customer satisfaction.

- Enhanced employee engagement and morale by empowering workers to contribute to process improvements.

- Increased flexibility and responsiveness to changing customer demands and market conditions.

Conclusion

The 8 wastes of lean manufacturing, also called a DOWNTIME, are critical to identify and eliminate waste in the production process. Implementing good quality control standards, including employees in process improvements, reducing extra motion, and eliminating extra processing, can enhance their efficiency and productivity, reducing cost and improving customer satisfaction.

Also Read: The 5 Why Analysis: A Powerful Tool For Root Cause Analysis

FAQs (Frequently Asked Questions)

What are the 8 forms of waste in lean management?

The 8 forms can be remembered using the acronym DOWNTIME, which stands for:

Downtime define

1. Defects

2. Over Production

3. Waiting

4. Non utilized talent

5. Transportation

6. Inventory

7. Motion

8. Extra Processing

What is downtime in lean manufacturing?

Downtime in lean manufacturing refers to the period when equipment or machinery is not operational due to maintenance, breakdowns, changeovers, or material shortages. It disrupts production flow, leading to delays and increased costs. Minimizing downtime is crucial in lean manufacturing to maximize productivity and minimize waste.